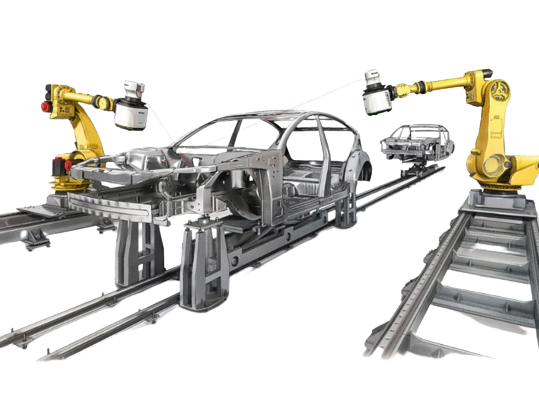

The APDIS IntelligentQuality Stations from Nikon provide flexible, fully automated CMM inspection systems with fast set up, high productivity, and real time quality results & analysis.

With the ability to measure over six times faster than traditional CMMs, be installed on the shop floor, and enhanced by ease of programming, the APDIS IQ stations provide unparalleled productivity, flexibility and simplicity for a CMM system. Precision measurements of features can be made without adapters, probes or coatings to high accuracy and repeatability, allowing quality control feedback quickly and easily where it’s needed.